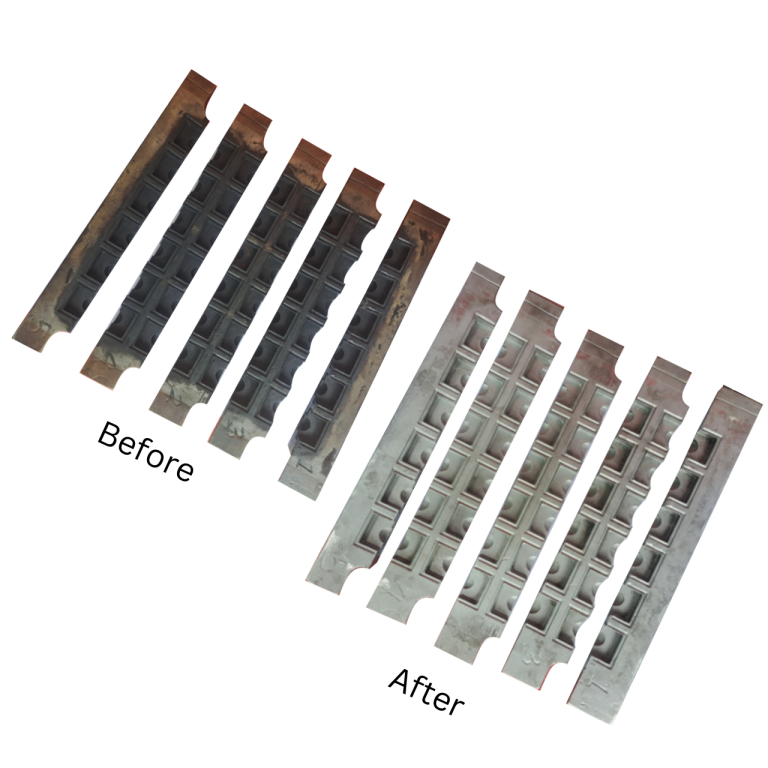

Ultrasonic Mold and Dies Cleaner

Special Features

- Efficiency: Ultrasonic cleaning reaches intricate details and crevices of molds and dies that may be challenging to clean through traditional methods.

- Time-saving: The automated nature of ultrasonic cleaning reduces the manual labor required for cleaning, leading to faster turnaround times in production.

- Gentle on Equipment: Unlike abrasive cleaning methods, ultrasonic cleaning is gentle on molds and dies, minimizing the risk of damage to critical surfaces.

- Consistency: The automated process ensures a consistent and repeatable cleaning cycle, improving overall cleanliness and quality.

- Environmentally Friendly: Ultrasonic cleaning often requires less use of harsh chemicals compared to traditional cleaning methods, making it a more environmentally friendly option.

In summary, ultrasonic mold and die cleaners offer a powerful and efficient solution for maintaining the cleanliness and functionality of molds and dies in industrial processes.

| SPECIFICATION | SMC-60A | SMC-120A | SMC-240A |

|---|---|---|---|

| Tank Size | 500x300x300mm (120mm dearance) | 600x400x350mm (150mm dearance) | 750x550x350mm (150mm clearance) |

| Basket Size | 400x250mm | 500x350mm | 650x500mm |

| Tank Capacity | 30L | 65L | 110L |

| Ultrasonic | 600Watt | 1200Watt | 2400Watt |

| Electrolysis | DC8V 50A | DC8V 100A | DC8V 200A |

| Heater | YES | YES | YES |

| Circulation | YES | YES | YES |

| Filter | YES | YES | YES |

| Pressure Gauge | YES | YES | YES |

| Digital Timer | YES | YES | YES |

| Electric | 220V 3,5KVA | 220V 7KVA | 220V 12,75KVA |